Crane Simulation, for virtual crane operation training.

Cranes are important equipment used in construction or factories which require moving of large objects or materials such as for constructing buildings, bridges, dams, mines or even in certain types of factories such as sugarcane factories. Statistics show that Thailand has more than 20,000 registered cranes larger than 1 ton in use. The law stipulates that crane operators must undergo both theoretical and practical training for 18-24 hours. In addition, the must take refreshment and skill update training every 2 years. However, the problem is that there are only about 10,000 people who have been trained and licensed to operate cranes throughout the country. This means that for every two cranes in operation, only one has a properly trained driver.

“Since the training course costs about 25,000 – 35,000 baht per person, most crane operators who actually come in to receive training are employees of large and medium companies, which total only about 250 companies for the whole country. On the other hand, companies owning only 1-2 cranes typically hire trained operators to provide training for their employees, renting or buying less expensive cranes from China to use for training. However, despite the reduced cost there are many risks, including having a trainers who are not really proficient or lack proper teaching skills, and the chances of accidents occurring during training are very high.”, said Mr. Klaas Charoenratchadet from Class In Co., Ltd., a training school for crane operation.

That is how the Crane Simulation Training Program originated (virtual crane operation system) with the support of the Program Management Unit for Competitiveness (PMUC), with the main objective being to create a virtual crane operation and control system similar to flight simulation training.

“Training with a real crane, there are two main risks, one being the opportunity cost of using a crane for training, which could otherwise be rented out for 15,000 baht or more per day, reducing the company’s revenue. And second, the risk of damage to the cranes during training due to chances of operator’s error leading to an accident, in addition to the normal wear and tear, affecting the useful life of the machines. A training simulator can help overcome all these limitations,” said Mr. Klaas, referring to how the project began.

Assoc. Prof. Anupong Songprapha, Head of the Medical and Environmental Instrument Research Laboratory (MERL), Department of Physics, Faculty of Science at King Mongkut’s Institute of Technology, Ladkrabang, as a co-developer responsible for the integration and application of knowledge about automation systems, sensors, and virtual reality, as well as for the design of virtual reality lessons in support of the simulation training program development, said the following about the steps entailed in the system development process.

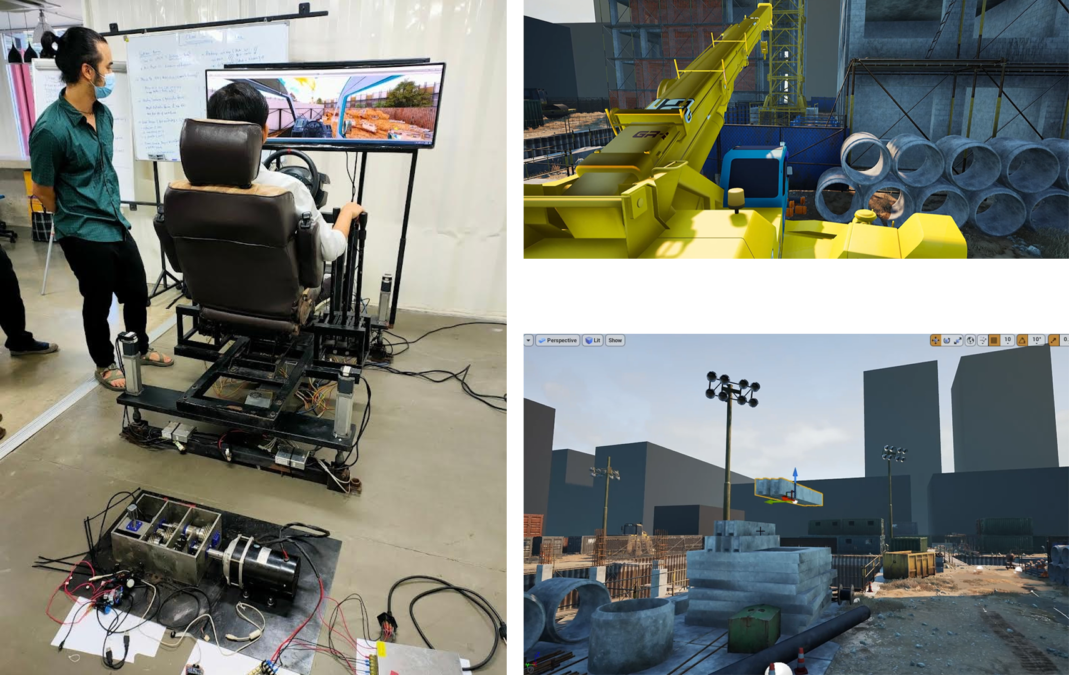

It all starts with collecting image data and workflows, and the actual movement of the 25-ton model TADANO crane, which are operated by highly experienced operators in various situations in order to build the training simulation courses, integrating both the operation aspect including all hardware and equipment functions, as well as the software aspect of the system which processes data from the trainer’s control and then translating it into virtual images appearing on the screen for the trainees to see and control as if they were actually operating the crane themselves. Initially, various situations will be developed to give trainees an opportunity to experience and operate the cranes in close-to-real operating situations, totaling 80 scenarios. Additionally there are simulated scenarios which can test different lifting situations, all combined to no less than 40 hours worth of training content, all of which are in accordance with the training process detailed in the announcement and guidelines of the Department of Labor Protection and Welfare

“We want the simulator to help make our training courses both safe and as close to real training standards as possible, so we designed a Crane Simulation Prototype that focuses on designing the overall structure to resemble a real crane, which has vibration and tilt functions by installing a hydraulic system that can shake the crane vertically, as well as a 360 degree rotation system [Swing 360] with an electric motor to rotate the crane. Additionally, there is a simulation system in the form of a virtual game and computer graphics to allow the trainees to feel as if they are in the cockpit of a real crane as much as possible. At the same time, we are developing an Online Training Simulation system for the general public to practice online using a typical computer mouse and keyboard before going in for the real training.”

Assoc. Prof. Anupong said that now the research team has designed the curriculum structure and style to create enjoyable, safe, and accurate training experience for trainees, which will be divided into basic knowledge of safe operation and of machine functions, with more challenging lessons as the hours of practice increase.

Mr. Klaas, as the person in charge of the project, said that the use of the Crane Simulation system to help in training crane operators, has served to increase hands-on practice hours with the training fee running approximately 15,000 baht per person. The company also plans to manufacture and install crane simulators for all 10 training centers, and aims to sell them to 40 other training centers. It is expected that 50 crane simulators will support training of approximately 1,500 operators per year, enabling all untrained crane operators to become trained and licensed within 6 years.

“We hope that the development of this Crane Simulation system, in addition to benefiting the construction industry, moving of machinery, as well as supporting higher safety in the BCG industry, it can also be a model or prototype of a training business, as well as the business of selling driving simulation equipment.”