Research funding support by PMUC in the project to promote the medicinal herbs production industry to become a new industry in the country, with Asst. Prof. Rawiwan Charoensap, Ph.D., head of Integrated Herbal Innovation Center, Mae Fah Luang University, as the project leader, focuses on the development of integrated, end-to-end, herbs production process, starting from the development of the production of high-quality raw materials, selective breeding and propagation, cultivating, harvesting, storage for quality raw material output, research and product development to drive industrial production, as well as marketing promotion to enable delivery of quality products to end consumers.

The 20-year national strategic plan(years 2018 – 2037) calls for a push for a fully integrated medical industry as a new industry in the country, by promoting and supporting the development of high-quality commercial production of herbal products while adding value to traditional Thai herbs. This is important in driving the country’s progress, according to the long-term national strategic plan. Focusing on the northern region, which is an important area for growing traditional Thai herbs, the project aims to develop systems and analytical processes, encompassing certification and testing of raw materials and herbal products in accordance with ISO 17025 standards in order to promote the expansion of research in laboratories towards industrial level commercialization, as well as to encourage researchers and entrepreneurs to develop herbal extracts and herbal products that meet international standards.

Support by PMUC for the pharmaceutical and herbal manufacturing industry project as an up and coming industry in the country consists of automatic capsule filling machines, spray drying machines, cold pressed machines for oil extraction,

From the visit to see the progress of the project by the Director of PMUC and the High-value Food Program Subcommittee on May 27, 2022, the project has evidently moved forward and has been open to interested entrepreneurs in the northern region, as well as other areas across the country, providing assistance in technology transfer, product development, as well as consulting service on research and development and providing prototyping tools to many interested parties ultimately leading to products which are ready to enter the market in the future. In addition, the project administrators have also received advice from the subcommittee to consider and identify service objectives, such as expanding the market to neighboring countries, or primarily providing services to large factory operators, SMEs, or community enterprises, so that the project administrators can set realistic expectations and perform effective project management

Highlights of the project reflecting the underlying principle of Bio-Circular-Green Model (BCG) include the concept of applying green extraction technology to the project and the prototype plant. Green extraction technology is a technology that focuses on environmentally friendly processes, which does not cause polluting effects on both the producers and consumers, such as the use of alternative Carbon dioxide type solvents, reducing the use of solvents in the extraction process, using microwave technology combined with chemical solvents to shorten extraction time, or the use of left-over raw materials from the extraction process for other useful purposes, etc.

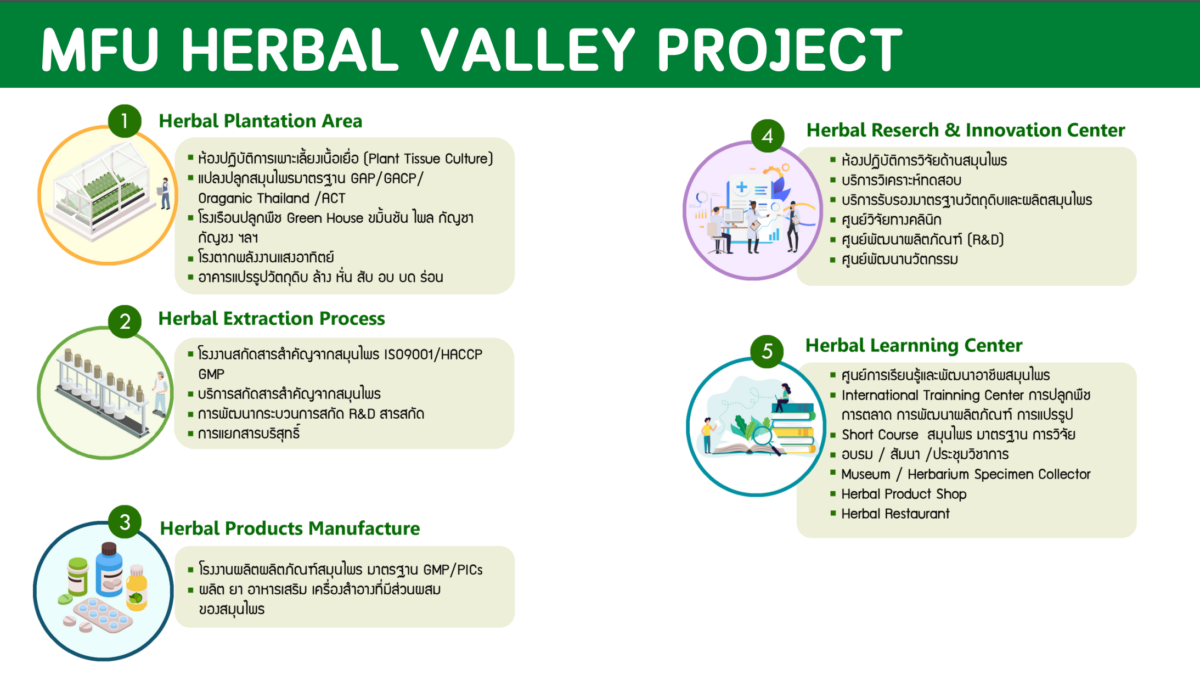

One-stop, end-to-end development of herbal products at the Integrated Herbal Innovation Center Mae Fah Luang University.

Integrated Herbal Innovation Center at Mae Fah Luang University provides comprehensive product development services in the northern region from 1) Knowledge base in Smart farm herb cultivation, such as tissue culture laboratories, planting plots, greenhouses, sun-dry domes, preliminary food processing within the Herbal Plantation Area. 2) Extraction of active ingredients, and production process development within the Herbal Extraction zone. 3) the prototype factory for production of herbal products, pharmaceuticals, dietary supplements and cosmetics with herbal ingredients within the Herbal Product Manufacture zone. 4) Herbal research laboratory services, providing tests, analysis, and certification of raw materials and herbs in the Herbal Research & Innovation Center and 5) center for learning and creating employment in herbs production, herbal product development, and product marketing within the Herbal Learning Center zone.

PMUC visited the turmeric cultivation demonstration plot under the Smart Farm system aimed at producing raw materials with consistent quality.

PMUC visited herbs processing plant.

Herb extraction plant.

The pride of researchers and the smiles of entrepreneurs and farmers.

Smile Green Tech Co., Ltd. is one business operator who came in to request services in the development of innovative products from herbal extracts, and received assistance in terms of developing a formula and transferring of knowledge in the whole production process, as well as received advice on applying for certification leading to the final product, “Compress ball massage cream”, which will be available on the market soon.

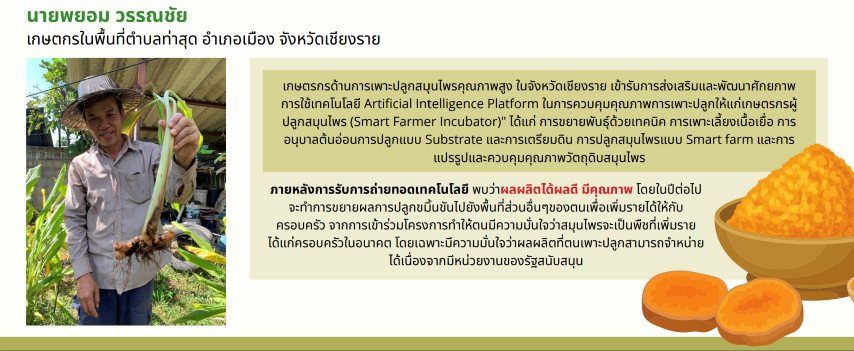

Mr. Payom Wannachai, a farmer in Chiang Rai Province, has received technology transfer assistance in the area of turmeric cultivation in a smart farm system. He has succeeded in expanding agriculture practices to high-quality herbs production.

For more details about the Integrated Herbal Innovation Center, Mae Fah Luang University:

Tel. 0-5391-7616 Email: cemedplants@mfu.ac.th Website: mpic.mfu.ac.th