PMUC joins an effort to support research and development of bio-fuels and promoting Bio-Oil from the Bio-refinery: an innovative platform for high-value extracts for the agro-industry and food industry, the first such initiative in the Northeast, by providing capital for machinery and equipment. The effort was in collaboration with Suranaree University of Technology, to develop innovative products to replace petroleum with alternative fuels such as yeast oil, coffee grounds, and high-value herbal extracts, with special emphasis on the southeastern region.

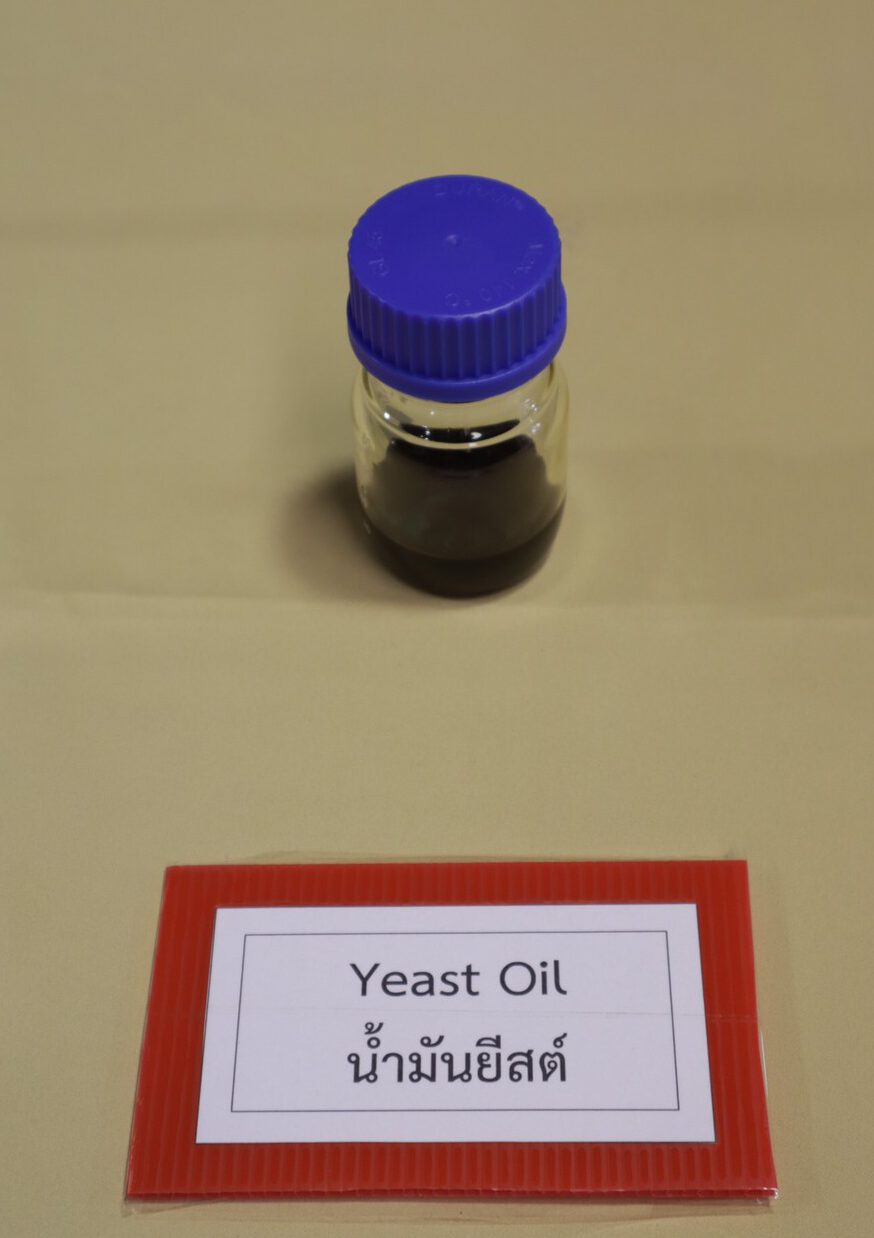

Yeast oil is one of many research and development projects to develop new alternatives in the production of bio-jet oil, bio-benzene and bio-diesel to promote progress in the country’s bio-fuel industry, benefiting from research funding support and infrastructure investment for food and high-value extracts industry by PMUC, with access to bio-refinery prototype plant at Suranaree University of Technology (SUT- BioProcessing Biorefinery Pilot Plant). Nowadays, bio-fuels are getting a lot of attention due to the continuously increasing price of crude oil in the world market. Due to the fact that Thailand does not have its own crude oil resources and is dependent solely on imports from foreign sources, there is a strong need to increase energy security, especially in the form of liquid and solid fuels. Segregated yeast oil can be applied as raw material for bio-fuel production, while at the same time helping to reduce greenhouse gas emissions. In practical application, it is very similar to crude oil.

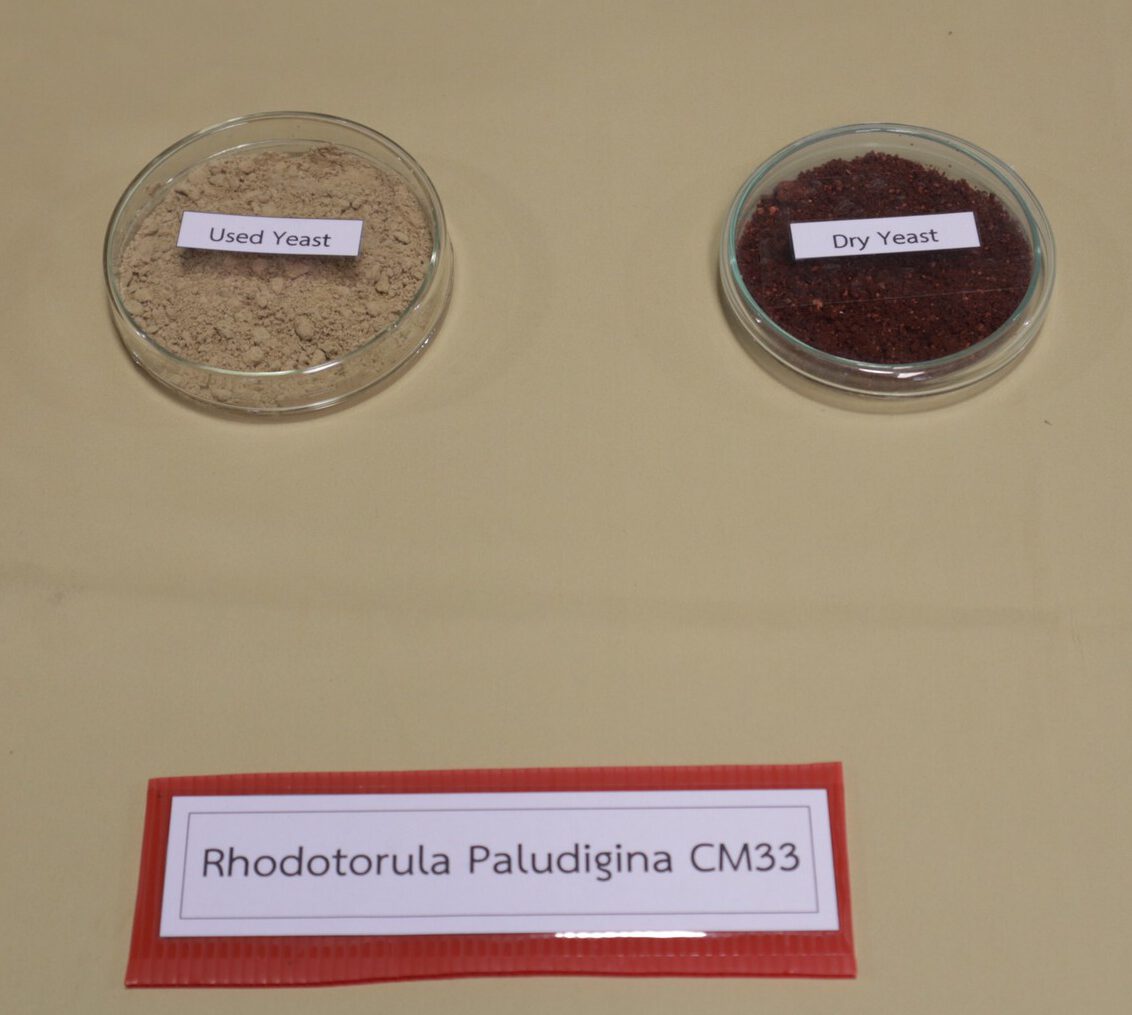

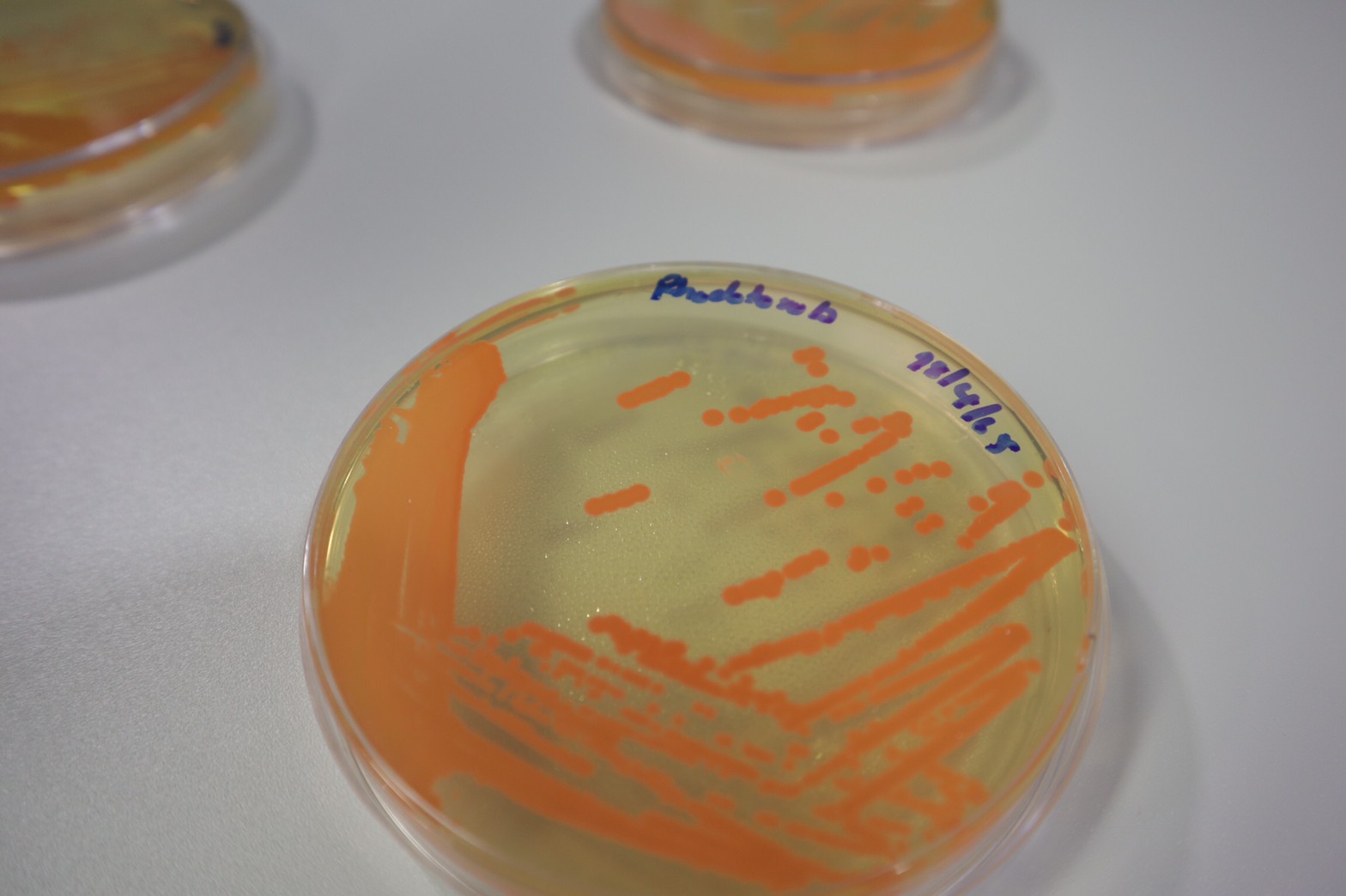

Yeast oil or oleaginous yeast, of Rhodosporidium paludigenum species, has many advantages such as being easy to cultivate, requiring less time and space, and can be cultured to have a high cell density. Yeast oil contains the main fatty acids that accumulate in yeast cells C14, C16 and C18, which are in the form of triglycerides. It is similar to the fatty acids in vegetable oils, which can be used to separate cells and extract oil. Then the output goes into the rapid pyrolysis process. (Fast-pyrolysis), and finally becoming bio-oil. The quality is then improved by using short path distillation and vacuum fractionation to separate and extract each type of oil. The final output is further refined to produce clean fuel for vehicles such as gasoline, jet oil or diesel fuel, etc.

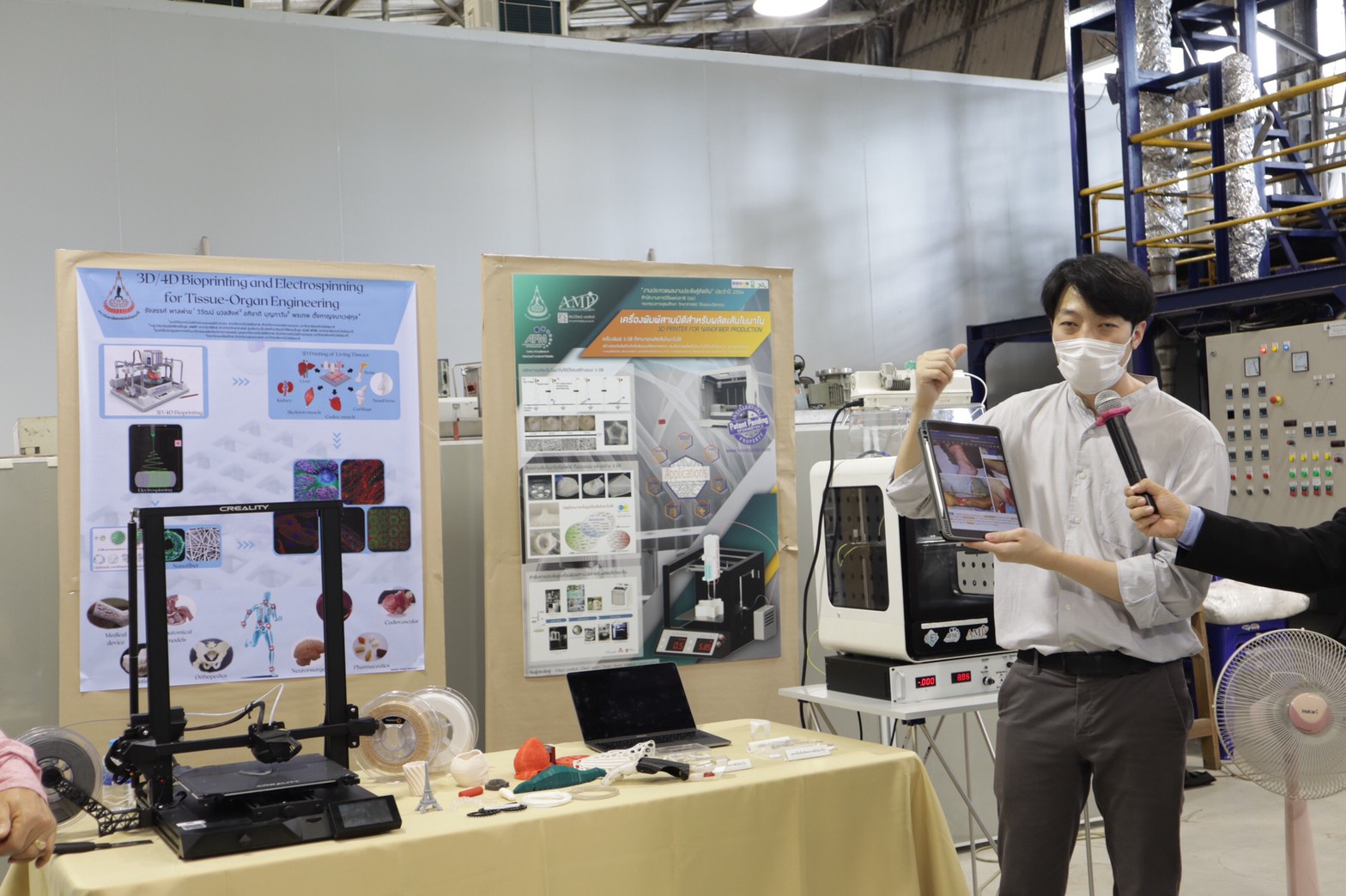

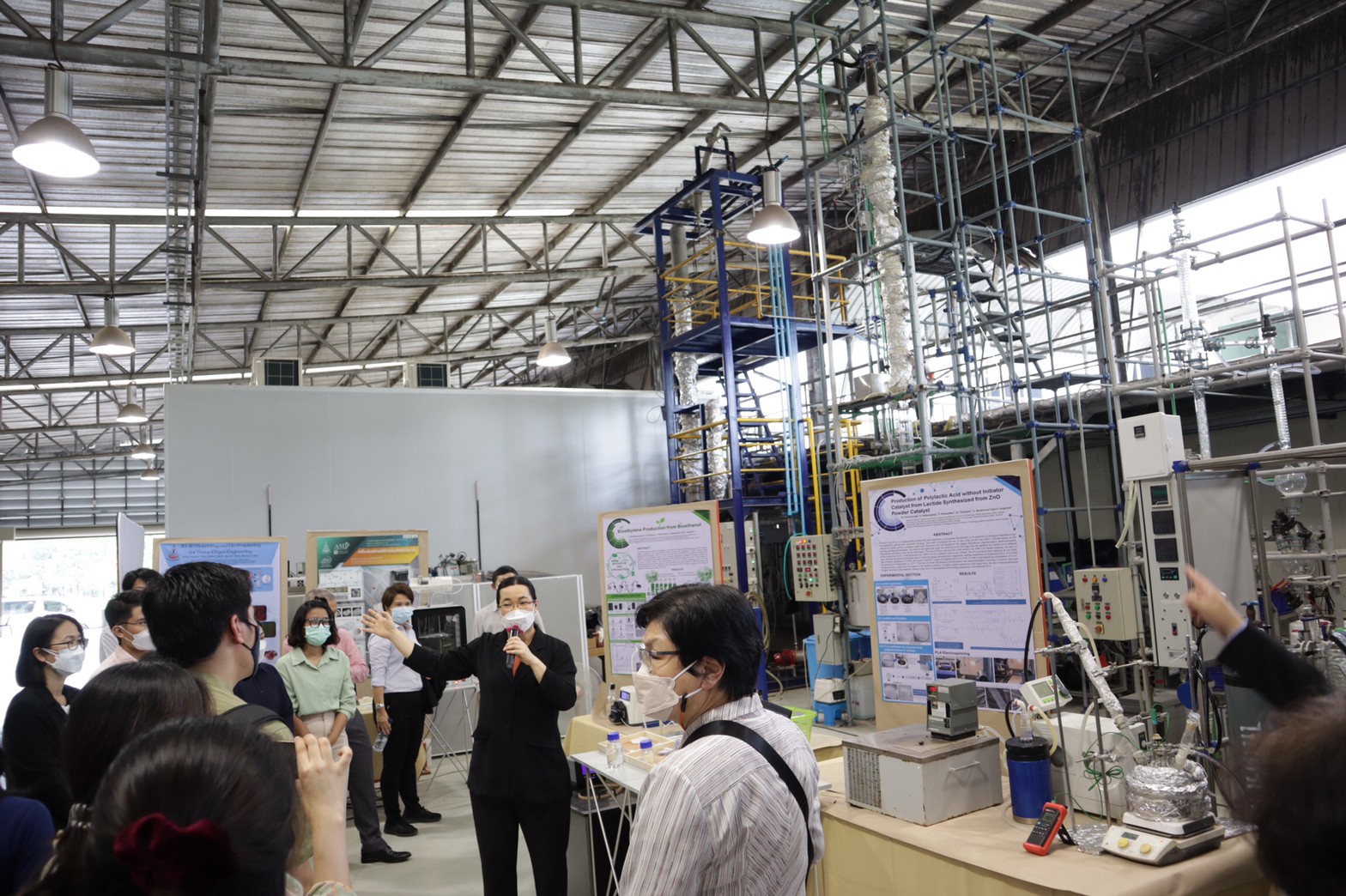

Suranaree University of Technology, as a science park in the lower northeastern region, has built a SUT- BioProcessing Biorefinery Pilot Plant, which was established to be used in operations for supporting research development or for industrial production, in support of the larger Bio-Economy development platform. This prototype plant consists of equipment and machinery used in extraction and refinery of high-value active ingredients for the agricultural and food industry in order to solve the problem of shortage in research and technology-assisted product development skills. The aim is to enable entrepreneurs of small and medium-sized enterprises (SMEs) and startups to be able to put their creative ideas into practice in order to achieve prototypes of innovative food products, without having to bear the risk of investing capital in expensive machinery.

Asst. Prof. Paphakorn Pittayachawan, Ph.D., project leader of the Innovation Platform for High-Value Essential Extracts for Agro and Food Industry from Bio-refinery Prototype Plant, expressed an intent on upgrading the process of extracting and refining high-value ingredients from cheap domestic raw materials, to potentially create a capability to produce at the industrial level, to develop learning resources for industrial operators to engage in real practical operations, to create innovative products that can be extended to commercial application, and to create added value for products to meet the standards and requirements of the global market. It is a prototype factory with Technology-ready-level (TRL) of 5-6 to support the construction of a high-value extracts factory on an industrial scale and a Biorefinery Pilot Plant for the development of a bio-economy platform in the Northeastern region. The objective is to use the Bio-refinery Pilot Plant to provide production and testing equipment, as well as provide consultation, design and testing assistance for biological production processes in order to simulate product characteristics and production processes at the prototype factory level.

PMUC has provided funding support for equipment and tools to support high-value extract services for the agricultural and food industry, as well as for bio-refinery prototype factories, including:

High pressure homogenizer (Micro fluidizer) for use in reducing the size of different biopolymers such as xylan, mannan, and cellulose to be smaller at the molecular level. This is to avoid the use of chemicals.(chemical-free production) to make the process a environmentally friendly as possible.

The prototype plant-level filter press, which is necessary for the separation of sludge from the desired solution after the pre-treatment of various types of biomass or an organic solvent extraction process at 1000 liters for use in the manufacture of Xylan (xylan) and Xylooligosaccharide (XOS) cellulose.

3. Vacuum rotary evaporator with a capacity of 20 liters performs evaporation of water or organic solvents causing the concentration of phyto-chemicals such as marijuana oil or hemp oil, etc.

4. A fluidized bed drier is a spray drying method, which utilizes a spraying technique to spray liguid solution to make fine dust, which in turn is spray dried to enable rapid moisture evaporation and obtaining the desired dry powder product, such as dried yeast powder FOS, XOS, Xylose, Xylitol, etc.

5. Medium-pressure separator (Prep HPLC) is used for purification by chromatography. Monophasic purification with Fraction collector for CBD and THC oil. This medium-pressure separator serves to separate and collect large quantities of isolated samples.

The support from PMUC in the form of infrastructure capital, as well as equipment and machinery for a prototype plant will enable the development of high-value extracts for high-quality agro-food industry, achieving a standardized process, which serves as a basis for further development of value-added products. Furthermore, Suranaree University of Technology is also a multidisciplinary university that enables integration of research in science and technology, serving as a link between the research institutions and the private sector.