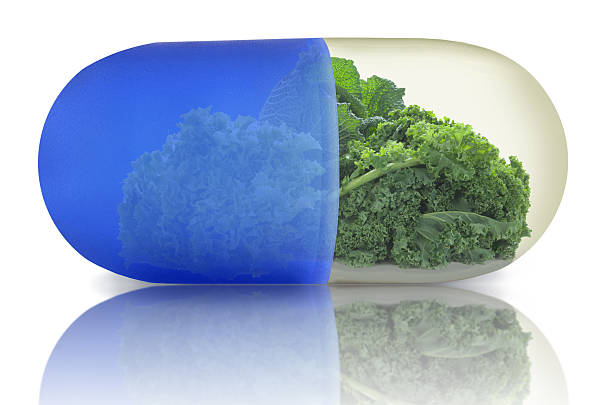

The innovative product, “freeze-dried kale sprouts in capsules”, is a result from the project, by King Mongkut’s University of Technology Thonburi, Bang Khun Thian branch,to develop a prototype factory for food production and health supplements to provide industrial services, support technology transfer, and promote a food innovation city in southern Bangkok and surrounding metropolitan areas. Other innovative product prototypes, which were presented to the Agricultural and High-value Food Program Subcommittee, PMUC, during their visit on March 30, 2022, served to confirm a successful effort to enhance the country’s competitiveness at the international level.

The prototype factory development project is intended to provide industrial services with an emphasis on SME development. The research and development effort to attain a prototype factory, laboratory and equipment will help drive the effort to create products that are ready to be commercialized. In addition, the projects also places importance on the developing high-quality personnel in the development of production processes, as well as on research and development to create prototype innovations to push towards successful establishment of a food innovation city for the country.

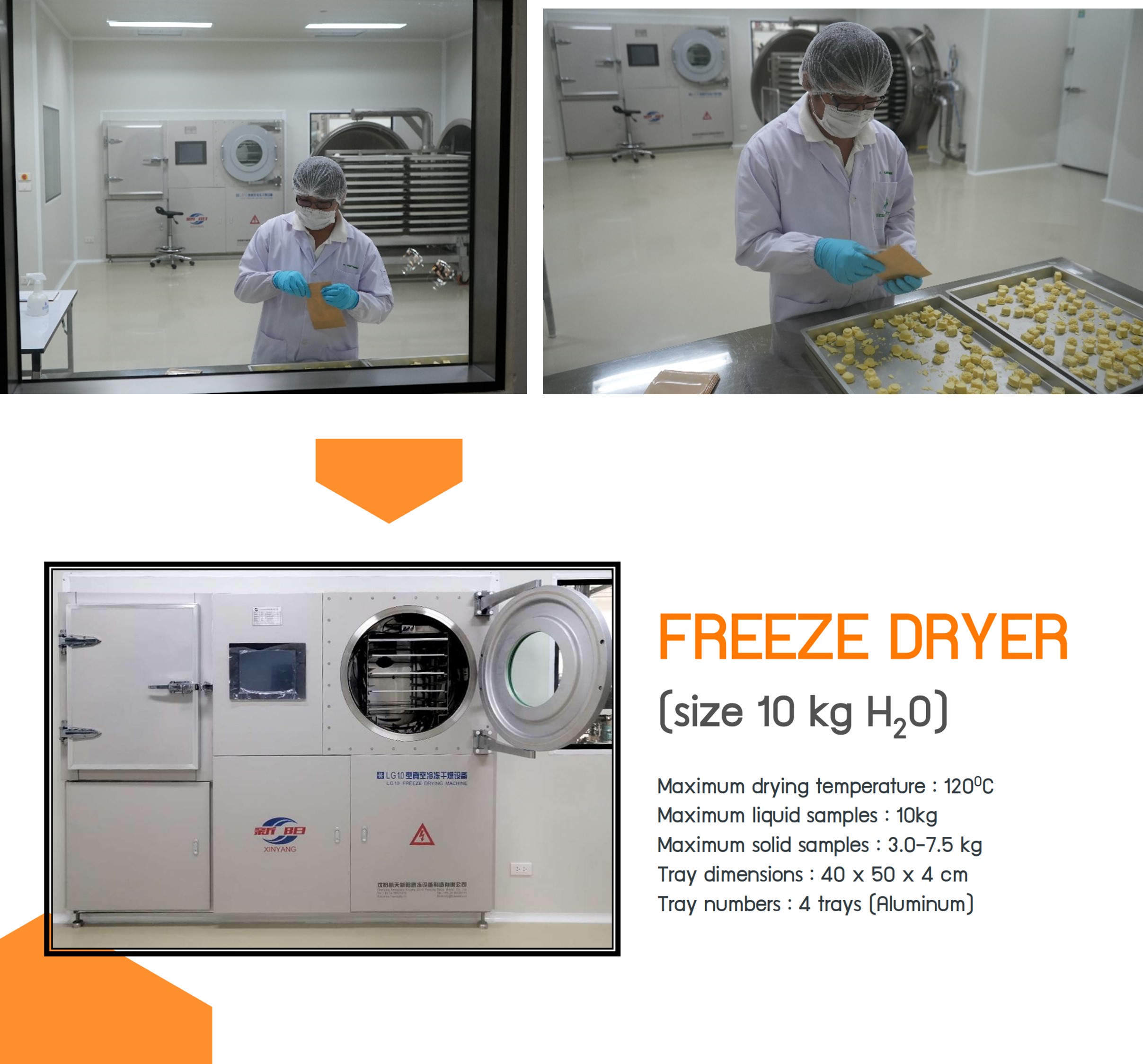

The prototype factory, located in the Bio-process Research and Innovation Building houses equipment for the traditional production process, such as high-pressure hot water extraction machine for extracting essence from plants, cold storage room, steam generator, various types of packaging machines, all serving SME companies to provide services in research and development of new products or solving problems in the traditional production process. A proposal was presented to PMUC to request funding to enable the prototype factory in driving research and development of advanced innovative products with modern technology equipment including spray dryer, vacuum dehydrator, high pressure extractor (Supercritical CO2 Extraction) and Freeze Dryer.

From experimenting with the use of laboratories and equipment, the research team has tried to produce “Freeze-dried kale sprouts” using a radiant-heat freeze-dryer, and a new product prototype that retains high-value ingredients was born, to be further packaged into capsules for easy consumption. It is an answer to the common problems faced by the private sector entrepreneurs in expanding production to commercialization.

Another great example of an output from the prototype factory is the production of dried monk fruit powder using the spray dryer, by extracting the active ingredients from the monk fruit using a high-pressure hot water extraction machine, and increasing the concentration of the monk fruit extract by using the vacuum evaporator allowing the product to retain full flavor and essence, etc. It is considered a prototype factory that is ready to support SMEs or entrepreneurs interested in product development, and to help justify and realize investment objectives at the industrial level in order to ultimately bring products to successful commercialization.

In addition to visiting to see the progress of the project, the subcommittee also gave further advice to the research team in the development of new products to become high-value foods, as well as considering the scale-up of services beyond prototype production, with the ultimate goal to help solve problems for entrepreneurs, especially in southern Bangkok and the surrounding metropolitan areas.