In an era where medical innovation and biotechnology play a crucial role in enhancing public health, the research and development of diagnostic test kits are essential for effective and accurate diagnosis and treatment. As a result, a collaboration network was established under the Innovation Hub project, known as the “Collaboration Network of Diagnostics Development Centers (CNDC).”

Recently, the Program Management Unit for Competitiveness (PMUC) under the Ministry of Higher Education, Science, Research, and Innovation (MHESI) took the initiative to host a forum, providing an opportunity for researchers and interested parties to meet and exchange experiences from various centers that have developed diagnostic technology and innovation through collaboration within the CNDC network. This forum also served as a valuable opportunity to reflect on the challenges and strategies for translating research into commercial production and sales, a significant step in promoting domestic innovations that can genuinely address the complex health issues faced by Thai society.

The Beginning of the Collaboration Network for Diagnostic Development Centers under the Innovation Hub Project.

The background of the Collaboration Network for Diagnostic Development Centers under the Innovation Hub Project (CNDC) involves cooperation among seven organizations: the Center for Research and Production for Disease Diagnostics and Food Safety Standards (ADDC), the International Standard Diagnostic Development Center, Chulalongkorn University (QDD Center), the Medical Device Research Laboratory, Naresuan University (MDRL), the Sensor Innovation Research Unit for Test Development and Production, Burapha University (RUSI), the Medical Biosensor Laboratory, Prince of Songkla University, the Center for Innovation and Standard in Medical and Physical Therapy Technology, Khon Kaen University (CISMaP), and the Center for Innovation in Genetic Diagnostic Development, Chiang Mai University (CIID).

Assistant Professor Somchai Chueawacharin, Ph.D., Director of the Center of Excellence for Medical Biotechnology (CEMB).

Assistant Professor Somchai Chueawacharin, Ph.D., Director of the Center of Excellence for Medical Biotechnology (CEMB), which serves as the coordinating agency for various centers within the CNDC, shared the story behind the network. He explained that this network has been in place for about seven years, since receiving funding from the government at the end of 2017 through the Pracharath Initiative Project related to innovation and productivity enhancement (D1). The reason for establishing these centers is that there are many knowledgeable scientists and researchers in various universities across Thailand, but when it comes to developing any diagnostic kits, it often takes a long time and is primarily conducted within their own laboratories. Once completed, these innovations face difficulties in advancing further. The Council of University Presidents of Thailand (CUPT) recognized this problem and allocated a budget to key universities spread across different regions nationwide to establish centers with international standards and comprehensive facilities to support and facilitate researchers working in this field.

“CEMB acts as a coordinator, providing support, like a backer or promoter, enabling these centers to operate and secure funding systematically, thus saving costs in training. I would like to extend my gratitude to the PMUC for supporting the funding and operations in various aspects, especially during the initial phase when these centers were newly established, and the personnel lacked expertise in medical devices. There was training on international standards, ensuring that every center has now received ISO certification.”

Training activity for the personnel of the Pathology Laboratory, using CryoimmunostainingTM technology from X-Zell at the Pathology Laboratory of North West Hospital in Frankfurt, Germany, July 18-23, 2023.

In addition, various fundamental research projects have been conducted, such as diagnostic test kits for disease detection, food safety testing kits, standard reference materials for testing, and medical standards. Furthermore, an efficient database has been developed by updating product and service databases, showcasing the expertise of each center, and creating English-language websites. Workshops and training sessions have also been organized in various fields, such as production process standardization, business feasibility analysis (Freedom-to-operate; FTO), medical software development, and intellectual property valuation (IP valuation), to enhance the network’s capacity in expanding personnel development to the private sector, by offering training to companies that lack knowledge in diagnostic test kits.

At the same time, the outcome from this strategic collaboration has been the establishment of international standard production facilities, such as ISO 13485/CE Mark, along with medical device innovations that meet global standards. An online technomart emerged during the COVID-19 period, and participation in various medical exhibitions or trade fairs such as MedLab, ThailandLab, and Medical Fair drew considerable interest from many business operators. With a strong network, diverse product champions, and a well-structured database, one can simply type the keyword “CNDC” to access detailed information on technologies and various centers.

The expected outcome is to support the emergence of future industries (New S-Curve), particularly in the fields of medicine and public health, and precision medicine, helping Thailand reduce its reliance on imported technologies.

Highlighting the expertise and key roles of each center under the CNDC network:

Let’s begin with the Center for Innovation and Standardization of Medical Technical and Physical Therapy at Khon Kaen University (CISMaP). Professor Patcharee Jeeranaingun, an advisor to the center, stated, “We aim to establish excellence in the fields of medical technical and physical therapy innovations at an international level through collaboration with partners from various sectors to bring technology and innovation into commercialization.”

From 2017 to 2020, CISMaP received a budget of 22,855,464 Baht from the D1 Public-Private Collaborative Project (Aging Innovation Hub) to develop a Fourier-Transform Infrared Spectroscopy (FTIR) instrument for analyzing chemical structural components, a molecular laboratory/proficiency testing laboratory (PT lab) for certification, and Lateral Flow Test Strip and Biosensor kits. Subsequently, in 2020-2021, it received 5,268,600 Baht in funding from PMUC to further develop innovations and services to meet international standards, thereby enhancing competitiveness, such as obtaining PT Provider certification for an automatic culturing program.

Professor Patcharee Jeeranaingun, Advisor to the Center for Innovation and Standardization of Medical Technical and Physical Therapy at Khon Kaen University (CISMaP).

CISMaP specializes in analyzing the properties and chemical characteristics of materials, offering analysis services for kidney stone composition using infrared spectroscopy at a service fee of only 560 Baht per sample, with a 40% annual growth rate in the number of samples submitted for testing. It also provides an artificial intelligence program for assessing biological and organ age by measuring aging from blood test results, comparing biological age—representing the true age of the cells and internal organs—with calendar age, along with personalized recommendations for lifestyle changes or behavioral adjustments to slow aging or disease progression in specific organs, such as the heart, kidneys, liver, and pancreas.

The standout innovation that has been applied for commercial use is the “Thin Film Microbial Storage Material.” It started as a research project funded at the undergraduate level by the Faculty of Medical Technology, Khon Kaen University, in 2018. This material was developed for use in testing the efficiency of automatic blood culture systems and for evaluating the proficiency of laboratory personnel. It has high stability, can be stored at 4ºC for up to a year, and remains stable even when transported at room temperature for up to two weeks. In 2023, two private companies—Innomed (Thailand) Co., Ltd. and Firma Co., Ltd.—joined forces to expand the market, bringing almost 100 laboratories across the country into the fold.

Meanwhile, a noteworthy development is the ongoing effort to develop additional disease testing kits. However, a significant pain point remains: medical consumables still need to be imported, making it challenging to compete in terms of cost. Therefore, CisMaP aims to produce these materials domestically through its research unit for antibody and recombinant protein production. The goal is to use these materials in test kits for detecting Staphylococcus aureus, which causes bloodstream infections. A prototype has already been developed, and within the next three years, the team expects to commercialize the product under ISO 13485—a global standard for quality management systems for medical devices, encompassing design, development, implementation, and maintenance of quality management systems to ensure compliance with the defined standards.

The CISMaP Center has met with government agencies within the ASEAN regional cooperation group, such as the Faculty of Medical Technology, University of Health Sciences, Lao PDR.

The Chulalongkorn University International Diagnostic Development Center (QDD Center), located at the Faculty of Science, specializes in diagnostic work, particularly in the development of Lateral Flow Test Strips. The center provides comprehensive services from production and development to method validation, ensuring that related research on test strips meets international production standards. Consequently, the test kits developed are accurate, reliable, and ready for commercial production. At the same time, the center is preparing prototypes in sufficient quantities to be used in clinical/field trials to verify the accuracy of rapid test kits according to international standards and is ready to transfer technology for industrial-level production.

One of QDD Center’s key roles in 2022 was to collaborate with the Faculty of Veterinary Science, Chulalongkorn University, and the Biotechnology and Genetic Engineering Research Institute to develop a progesterone test kit for use in swine farms. This product, part of the center’s pipeline, helps distinguish female pigs ready for breeding, thereby increasing the number of pigs and reducing farming costs. MSD Animal Health has acquired the rights to purchase and use this technology and will distribute it starting in China before re-entering the Thai market. This marks a significant milestone in transforming shelf-ready research into real-world innovation with practical applications, ready for global export.

In the future, this test kit will be expanded for use with goats, sheep, cattle, and buffaloes, which are economically significant animals in Thailand. The test kit is a strip test that is easy to use, lightweight, and portable, with a quick testing time of just 15 minutes and an accuracy rate of up to 95%. Furthermore, it is affordable. This project received funding support from PMUC and assistance in negotiating with the business sector (MSD Animal Health), as well as advisory support for FDA registration, IP registration, licensing agreements, and sales contracts. The Chulalongkorn University Technology Center (UTC) also provided business innovation management advice. The technology developed by the research team has been advanced from laboratory research to commercial innovation and has received production standard certification by the QDD Center.

Recently, in collaboration with the Faculty of Medicine, Chulalongkorn University, a new innovation has been launched—a microalbumin urine test kit that allows for self-screening of early-stage kidney disease. This test kit is easy to use and provides simple results, yet it is highly accurate, making it beneficial for proactive health policies. Doctors and healthcare professionals can utilize it to screen for early-stage kidney disease in patients. Detecting kidney disease at an early stage raises patient awareness and encourages lifestyle adjustments to reduce the risk of chronic kidney disease. The test kit was developed using immunological principles by postgraduate students in the field of Biotechnology and was further enhanced by scientists. It has received ISO 13485 certification and was made available for sale mid-year by BJC Healthcare.

Prof. Sirirat Rengpipat, Director of the Chulalongkorn University Diagnostic Development Center (QDD Center).

Prof. Sirirat Rengpipat, Director of QDD Center, mentioned that the QDD Center has been certified by the Food and Drug Administration (FDA), Ministry of Public Health, as a facility meeting international standards for medical device production. This demonstrates the expertise of the personnel and the quality of the scientific equipment used. The center is also equipped to serve as an independent third-party verification unit, as well as to monitor the quality of products derived from research conducted by various teams at Chulalongkorn University. For this innovation, the center will conduct random checks on test kits from the market to verify their accuracy and precision, thereby enhancing confidence in the results for preliminary kidney health analysis. This is considered an innovation that promotes high standards for test kits available in the market, ensuring superior quality and quick results.

Additionally, QDD Center, which operates smoothly thanks to funding support from PMUC, collaborates with other agencies as well. It provides services and collaborates in research and development of diagnostic kits with research units within Chulalongkorn University, including the Faculty of Science, Faculty of Medicine, Faculty of Veterinary Science, Faculty of Allied Health Sciences, and the Institute of Biotechnology and Genetic Engineering. It also works with external research institutions, providing technology transfer for diagnostic kits verified for accuracy to related private companies to enhance production capabilities. It also coordinates with government agencies that benefit from the use of these kits, such as the Department of Livestock Development, public hospitals, and health service centers, for further promotion and implementation of these validated kits.

Regarding the Medical Device Research Laboratory at Naresuan University (MDRL), it plays a key role in supporting facilities and equipment for prototype medical device production according to medical device standards. It also provides laboratory testing services that meet international standards (ISO 15189, ISO 15190, and ISO/IEC 17025) to support research in medical sciences and prototype medical device production. Furthermore, it serves as an academic hub for studying laboratory standards, medical device standards, and test kits for students at Naresuan University, as well as for establishing strong networks with other centers under the Center of National Diagnostic Cooperation (CNDC).

Assoc. Prof. Wanwisa Tribuppachatsakun, Ph.D., Head of the Medical Device Research Laboratory, Naresuan University (MDRL).

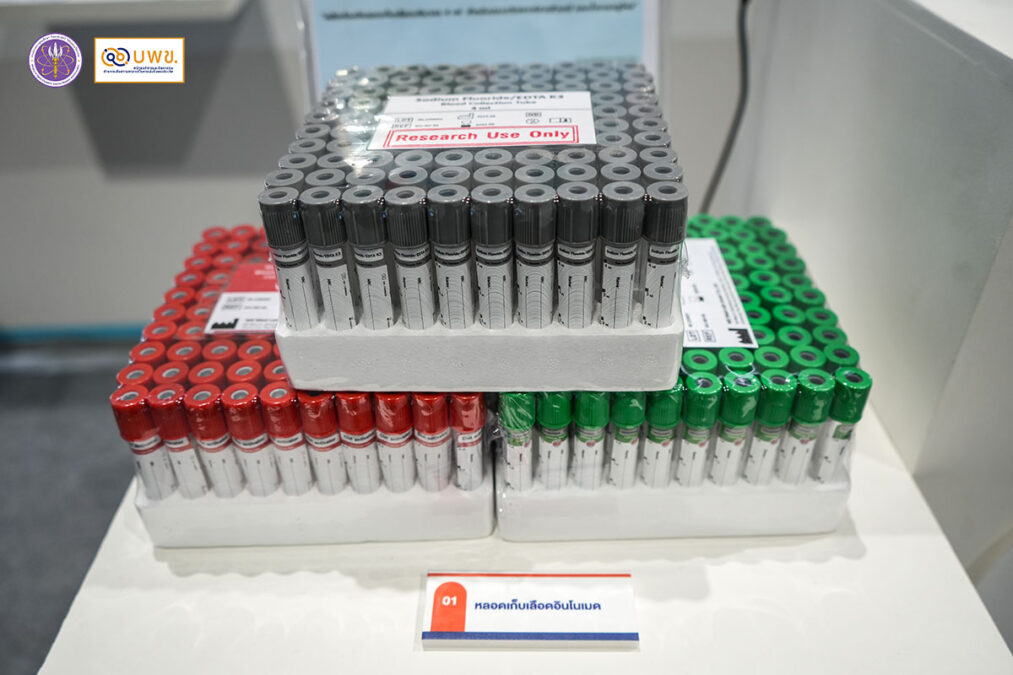

Assoc. Prof. Wanwisa Tribuppachatsakun, Ph.D., Head of MDRL, stated that they received funding from PMUC for two projects. The first is the development of Innomed vacuum blood collection tubes, which meet international standards for the analysis of biochemical substances and glucose levels. These tubes can maintain glucose stability for up to 8 hours after blood collection, reducing time, costs, infection risks, errors, and the number of blood samples needed. Currently, 50 hospitals have adopted this product.

The second project, also funded by PMUC, involves the development of processed materials and reference materials to be used as proficiency testing materials in medical laboratories according to ISO 13485 and ISO 17034 standards. Initially, 10 types of reference materials have been introduced, with about 30 more in the pipeline. Reference materials are essential and challenging to develop for new medical devices, as they are necessary for calibration. Currently, both products have been further developed for commercial and market use in collaboration with private companies.

Innomed Vacuum Blood Collection Tube.

MDRL is currently developing a nicotine antibody clone to detect nicotine metabolites in urine and saliva. Previously, Thai researchers had to import antibodies, which were costly and only suitable for research use. They could not be commercially expanded due to significant cost differences or contractual restrictions. This development addresses such pain points, with MDRL collaborating with the Center for Innovation in Swine Management and Production (CISMaP) at Khon Kaen University, which specializes in urine analysis. For reference materials like microbovine, they are working with the QDD Center at Chulalongkorn University.

This is an interesting story of the background of CNDC and some of its affiliated centers. Details of the other four centers and additional intriguing topics will be covered in the next installment. Stay tuned.