From the primary mission of the Program Management Unit for Competitiveness (PMUC) under the Ministry of Higher Education, Science, Research and Innovation, which aims to elevate Thai entrepreneurs by accelerating the application of research and innovation to create high-value products, goods, and commercial services, the goal is to enhance the nation’s competitiveness, boost economic value, and foster a sustainable low-carbon society.

The results of this mission have led to research projects funded by the PMUC in eight key industry sectors of the country and four enabling groups that facilitate the commercialization of research. Many of these projects have been extended into commercial production and include research outcomes that are first-of-its-kind in Thailand, with a tangible impact on economic and social development.

To inspire and set a successful example for entrepreneurs interested in applying research and innovation, including advanced technology and deep technology, to effectively boost their competitiveness, PMUC has organized the inaugural ‘PMUC Country 1st Award: Research that Transforms the Nation.’ Thirteen projects were selected from 1,600 PMUC-funded projects, with completed research ready for commercial adoption. Another key criterion for this award was that the research must be a first-of-its-kind in Thailand and have a significant impact on economic and social development.

PMUC’s mission is to drive the Thai economy forward by using research and innovation to transform the nation.

On this occasion, Assoc. Prof. Thongchai Suwansichon, Ph.D., Director of PMUC, provided further details about the ‘PMUC Country 1st Award: Research that Transforms the Nation’:

“PMUC’s core mission is to elevate entrepreneurs by accelerating the application of research, innovation, and technology to develop products, goods, services, and even platforms that generate high commercial value. We believe this will be a key mechanism in driving and enhancing the competitiveness of the Thai economy.”

“In the past, PMUC has focused on creating high-value products and services that meet international standards. We also emphasize developing and promoting an increasing number of Innovation Driven Enterprises (IDEs) in the country to foster collaboration and encourage public and private sectors to invest in research, thus accelerating the development of Thai innovations into global markets. Moreover, we provide funding to enable businesses to enhance their workforce skills in line with modern industries, elevate infrastructure to support the expansion of research into commercial applications, and support research funding to drive Thailand’s Soft Power.”

Assoc. Prof. Thongchai Suwansichon, Ph.D., Director of PMUC.

“Additionally, PMUC supports research funding in eight sectors: High-Value Foods, Health and Medicine, Energy, Chemicals and Biochemical Materials, Tourism and Creative Economy, Digital Platforms, Circular Economy, Future Transportation Systems, and Logistics and Railway Systems. Moreover, we support four national-level mechanism plans to drive the nation forward: National Quality Infrastructure (NQI), Global Partnership for International Cooperation in Science, Research, and Innovation, Deep Science and Technology Accelerator Platform for incubating and developing science and technology-based businesses, and promoting Innovation Driven Enterprises (IDEs) to increase the number of such enterprises in the country.”

The Program Management Unit for Competitiveness Enhancement (PMUC) received a grant from the the National Science, Research, and Innovation Fund, SRI Fund, to allocate for research aimed at enhancing the nation’s competitiveness from 2020 to 2023. We have supported over 1,265 research projects, totaling more than 7.652 billion baht.

To date, we have funded over 1,600 projects, with a total value exceeding 11 billion baht. It is very encouraging to see the private sector taking interest in utilizing research and innovation. Over the past four years, private sector co-investment in research with PMUC has amounted to no less than 2.4 billion baht across nearly 800 projects. According to an economic impact assessment, which was a random evaluation conducted by experts, the economic impact has been estimated to be no less than 3.6 billion baht per year for the assessments conducted in 2020 – 2021.

On the occasion of the “Ministry of Higher Education, Science, Research, and Innovation (MHESI) Fair,” PMUC has organized the ‘PMUC Country 1st Award’ ceremony for the first time in Thailand under the theme ‘Research Changing the Country.’ We selected 13 outstanding research projects from among 1,600 PMUC-funded projects, spanning 8 key industrial sectors and 4 enabling factors for driving research towards commercialization. Each of these projects has completed research outputs that are ready to be applied commercially. Moreover, these research outcomes are the first of their kind in Thailand and have had a significant impact on economic and social development.

Review of the 13 Outstanding Research Projects Winning the ‘PMUC Country 1st Award: Research Changing the Country’

To provide further details on the 13 projects that received the ‘PMUC Country 1st Award: Research Changing the Country,’ we present an overview of these projects along with their unique features.

Meticuly: Personalized Artificial Bones by Meticuly Co., Ltd.

The personalized titanium artificial bones, designed from patients’ CT scan images, have been in development since 2017 to meet the goal of surgeons who seek the best possible outcomes for every surgery in the shortest amount of time. Meticuly designed personalized titanium artificial bones and surgical assistance devices using AI technology, internationally standardized manufacturing processes, and effective collaboration with surgeons to help them achieve these goals smoothly. This innovation is another option for personalized healthcare that addresses the varying needs of each patient.

Meticuly Co., Ltd. was founded by a group of engineers dedicated to advancing medical innovation, aiming to help surgeons perform surgeries more conveniently and accurately than with traditional methods, while providing patients with better treatment options.

The technology used in producing personalized titanium artificial bones is advanced 3D printing technology known as Selective Laser Melting (SLM). This 3D printing method shapes the titanium bones through a laser melting process, enabling the production of strong, mechanically robust titanium bones with complex, customized designs that meet individual patient needs with precision. Additionally, titanium has good biocompatibility, which reduces the risk of infection. Recently, Meticuly’s treatment outcomes have been published in internationally recognized medical journals.

Pegfilgrastim: A biologic drug to stimulate white blood cells for cancer patients undergoing chemotherapy, developed by Mahidol University and Siam Bioscience Co., Ltd.

In the medical and public health fields, it is well-known that biologic drugs produced using advanced biotechnological processes to enhance the effectiveness of treatment for severe diseases play a critical role. Particularly, monoclonal antibodies are a class of biologic drugs that are in high demand for treating cancer, autoimmune diseases, and other chronic conditions. However, Thailand still has to import these types of drugs from abroad.

Due to the complexity of research and development, manufacturing processes, and quality control, these biologic drugs are costly, limiting patient access. Therefore, it is crucial for Thailand to expedite research and development to produce these drugs domestically. However, the current limitation is that domestic pharmaceutical factories are not yet capable of handling such complex manufacturing processes. Instead, they can only produce or repackage drugs by importing key active pharmaceutical ingredients (APIs), especially those synthesized through chemical processes.

With the goal of enabling Thailand to be more self-reliant and to increase patient access to medication comprehensively, while also reducing the financial burden from importing drugs, Mahidol University and Siam Bioscience Co., Ltd. successfully developed a biologic drug that has been registered with the Thai FDA. This achievement marks the first locally developed Biologic API in Thailand, created from Technology Readiness Level (TRL) 1-9 (from API to Biosimilar).

The advantage of Pegfilgrastim is that it enhances patient compliance and is convenient for administration, requiring only one injection per chemotherapy cycle without the need to adjust the dosage according to the patient’s weight. All patients use a standard dosage of 6 mg per administration.

Prototype GMP-Compliant Extract Production Facility Using Medicinal Herbs (e.g., Kratom) to Promote Community Enterprises in Southern Thailand.

The geographical conditions in Southern Thailand are suitable for the growth of kratom, making it commonly found in both natural and home-grown settings in several southern provinces. Medically, kratom has been widely used around the world due to its properties in treating drug addiction. It is also utilized as a pain relief alternative to morphine, processed into capsules to relieve body aches, and included in energy-boosting formulations.

With the potential of the cultivation areas, diverse medicinal properties of kratom, and its recent legal reclassification removing it from the list of controlled substances, the idea emerged to elevate kratom production for medical and food applications. This initiative aims to enhance the competitiveness of Thailand’s food and pharmaceutical industries.

The project to establish a laboratory and prototype facility for the production of standard herbal extracts for medical and food applications, compliant with GMP standards, was initiated by the Institute of Medical Innovations Research, Prince of Songkla University (PSU). The project aims to study and experiment with using kratom as a model plant for setting up a standardized production system from upstream to downstream processes. This project is supported by research funding from the Program Management Unit for Competitiveness (PMUC).

The establishment of the GMP-compliant prototype kratom extract production facility for medical and food applications has contributed significantly to improving the efficiency of kratom production. Furthermore, it serves as a foundation for creating opportunities to position kratom as a potential future economic crop for the southern region of Thailand.

Beyond Horizon Train: A Thai-made train developed by King Mongkut’s Institute of Technology Ladkrabang (KMITL).

The “Beyond Horizon” train is a prototype passenger train, the result of research and development by a KMITL research team under the project “Development of a Prototype Passenger Train (Thai-made Train)” with funding support from the Program Management Unit for Competitiveness (PMUC) under the Future Mobility Systems plan. The project was carried out in collaboration with SinoGen-Pinphet Joint Venture Co., Ltd., with the State Railway of Thailand (SRT) adopting the research results to enhance railway services for the public. The shared goal is to promote the establishment of a railway vehicle manufacturing industry based on the principle of “self-reliance.”

This prototype passenger train car was designed and manufactured by Thai professionals using over 44% local content (or 76% if excluding the railway bogie). The train is of Luxury Class and Super-Luxury Class standards, among the most luxurious and modern in the region, inspired by first-class airplane seating to meet the demand for passenger train cars in the next 20 years, which is expected to require no fewer than 2,425 units.

The research team was able to produce this train car at a cost of 32 million THB, which is significantly more cost-effective than importing from abroad. This helps the country reduce its dependence on imported train cars by more than 30%, representing substantial economic savings. Additionally, the knowledge and technology gained from this project will be transferred to domestic enterprises and students, contributing to the sustainable strengthening of Thailand’s rail transport industry.

Most recently, on July 3, 2024, a special test run of the prototype passenger train “Beyond Horizon” was conducted to evaluate its performance and inspect the functionality of various systems and controls from Bangkok Apiwat Station to Chiang Mai Station. Moving forward, continuous testing will be carried out in conjunction with SRT’s locomotives to ensure compatibility with existing train cars in SRT’s fleet. Once all testing phases are successfully completed, the procurement process will commence to allow for commercial service in the near future.

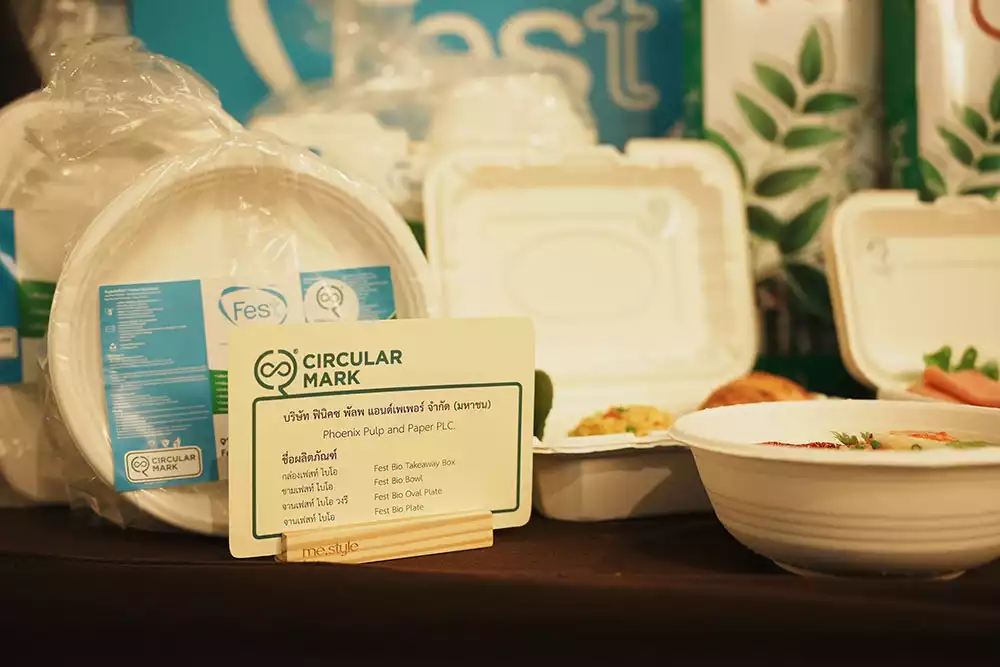

Circular Mark: A Certification for Circular Products by V-Green KU, Faculty of Environment, Kasetsart University

This research project, in collaboration with the Thailand Environment Institute Foundation, the Water and Environment Institute for Sustainability, and the Federation of Thai Industries, has developed the world’s first environmental certification for circular products, known as the “Circular Mark.”

The Circular Mark serves as a starting point for aligning with current global trade trends, reducing potential trade barriers in the future. It supports Thai businesses in expanding their markets widely, reinforcing their position as leaders in the circular economy, and enhancing the credibility of Thai brands and services on an international scale. The goal is to improve environmental quality and quality of life for both Thai society and the global community, while also enhancing Thailand’s competitiveness on the world stage.

The Circular Mark focuses on supporting five pilot target industries: agriculture and food, construction materials, plastics, packaging, and fashion & lifestyle. Businesses wishing to apply for the Circular Mark must meet specific requirements addressing issues such as resource efficiency, waste generation, greenhouse gas emissions, and other environmental impacts throughout the product life cycle.

In March of this year, it was announced that the project had successfully certified 26 companies as the first group in Thailand to meet the Circular Economy Management System standards for organizations. Furthermore, 34 consultants were developed, along with 20 auditors from 4 certification bodies (CB: Certification Body), which are now prepared to expand the scope of assessment and certification services for Circular Economy Management Systems for organizations.

Additionally, 500 individuals received new skill development training, and others gained practical knowledge and experience through the compilation of a practical guidebook based on the standard requirements of the Circular Economy Management System for organizations, which can be applied in the future.

Zero Wastewater Discharge by Thai Union Group Public Company Limited.

The issue of odor pollution caused by waste from the seafood production process, such as blood, fish steaming water, or waste contaminated with the internal organs of marine animals, being discharged into public water sources has been a longstanding problem for this type of industrial factory. Thai Union Group Public Company Limited, a global leader in the seafood industry, has initiated the “Zero Wastewater Discharge” project. This project is conducted under the research program “Development of a Zero Wastewater Discharge Treatment System Prototype,” establishing a learning center for wastewater treatment systems that recycle wastewater for reuse in the seafood industry. This initiative has been supported by the Program Management Unit for Competitiveness (PMUC), with Thai Union serving as a prototype factory for installing and implementing this system using Thai engineers, successfully establishing a comprehensive wastewater management standard. As of now, Thai Union is recognized as the world’s first seafood industrial factory that does not discharge any wastewater into public water bodies.

As a result, Thai Union Group serves as a model of an environmentally friendly industrial factory focused on sustainable development, aligning with the goals of carbon neutrality and the bio-circular-green (BCG) economy. This achievement is a key driver for Thailand to reach its target of sustainable development or the Sustainable Development Goals (SDGs) by 2030.

Previously, Thai Union’s factories required over 7 million liters of water per day for production. Today, the figure has been reduced to just 4 million liters per day. Furthermore, the Thai Union’s fish processing plant no longer discharges even a single drop of wastewater into public sources, resulting in an annual saving of 1,095 million liters of water (equivalent to a 45% reduction), which translates to an annual reduction of water costs by 27.8 million THB.

Bio-based Fire-Resistant Transformer Oil by the National Science and Technology Development Agency (NSTDA).

The research team began developing the prototype of EnPAT, a safe bio-based transformer oil derived from Thai palm oil, in 2020. This research project has provided opportunities for all relevant agencies to collaborate and integrate their efforts in pushing forward research achievements and promoting the widespread commercial use of bio-based transformer oil from palm oil across Thailand.

The EnPAT has a notable characteristic: its flash point is above 300 degrees Celsius, which helps prevent fire hazards from transformer explosions. Additionally, it is biodegradable, contributing to the improvement of public safety and quality of life through science and technology. This initiative also emphasizes the importance of establishing national standards that align with products developed from palm oil. Setting clear standards is a crucial step that will advance the country’s oleochemical industry and promote domestic usage. These standards will enable manufacturers to create quality products that are environmentally friendly. Recently, the results from pilot testing of EnPAT oil will be used to support the establishment of the first industrial product standard (Thai Industrial Standard – TIS) for bio-transformer oil in the country.

Moreover, bio-transformer oil is a product that can significantly enhance the value of Thai palm oil, increasing its value by as much as 565%. This is much higher than that of edible oil and biodiesel, which have value increases of only 67% and 23%, respectively. This development also boosts production capabilities, creating added value for palm oil products and elevating production from basic consumer goods to high-value industrial products and related industries.

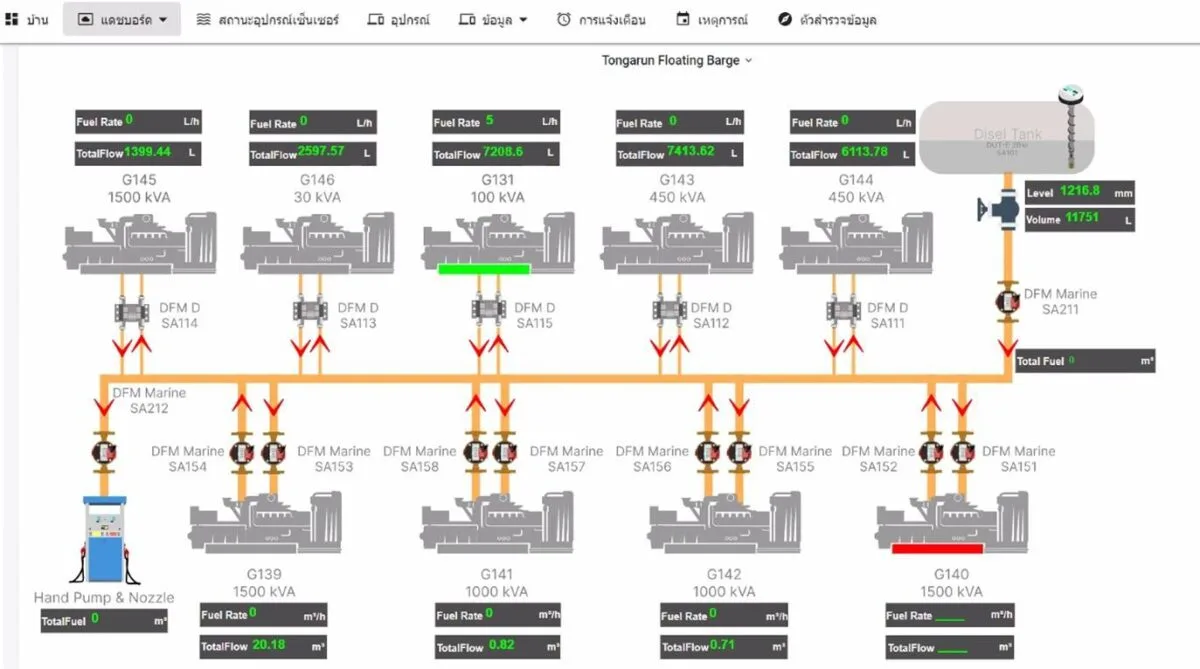

The logistics management platform, developed by Khon Kaen University in collaboration with SP Inter Marine Co., Ltd.,

utilizes the island of Koh Si Chang in Chonburi Province for the transshipment of large goods such as rice, agricultural products, animal feed, and fossil fuels, with transshipment volumes reaching up to 7.2 million tons per year. However, challenges include high logistics costs and a lack of real-time data management, resulting in delays in decision-making and operations.

To develop a river transport logistics system using a digital platform that enhances the efficiency of bulk cargo transshipment for export and import, researchers from Khon Kaen University have developed a logistics management platform. This serves as a software model to support the transportation and transshipment of bulk goods by appropriately allocating buoys and cranes according to the size of the vessels and types of products, thereby reducing costs and transshipment times. This platform also addresses the need for a database system to analyze and manage data related to the transshipment of large goods, along with a monitoring and tracking system that modernizes logistics indicators to align with changes in various contexts.

This project applies digital technology to measure energy consumption and manage big data in real-time for bulk cargo transshipment. It employs software for multi-period scheduling of cargo transshipment and a database and monitoring and tracking system to analyze big data on energy consumption. The system measures energy usage during bulk cargo transshipment using digital technology, develops a database, and creates prototypes/software to support bulk cargo transportation and transshipment.

Currently, the joint venture has expanded the use of the system to three out of seven buoys designated for transshipment. It is expected to cover all buoys within this year. Additionally, the project results have been disseminated to operators within the water transport business association to present detailed operational outcomes and share beneficial information with association members and related agencies, serving as a prototype guideline for developing modern logistics technology and management in the country.

The elevation of international hygiene standards, GBAC STAR, in the tourism and service industry is being undertaken by Prince of Songkla University, Phuket Campus.

The research and development project aims to elevate GBAC STAR hygiene standards in the tourism and service industry and is supported by the National Science and Technology Development Agency (NSTDA), the Office of the National Science and Technology Development Agency (NSTDA), and the Ministry of Higher Education, Science, Research and Innovation (MHESI). The initiative also collaborates with private sector companies such as Pizona Tour Co., Ltd., SEA Consulting Co., Ltd., C Partner Solutions Co., Ltd., and Bangsaen Beach Resort Co., Ltd.

This project is considered a proactive mission aimed at elevating the hygiene standards of operators in Thailand’s tourism and service industry to meet international standards. The application of global standards to enhance hygiene safety for Thailand’s tourism and service sector in this research is a concrete dimension of enhancing the country’s competitiveness, which will significantly build confidence in hygiene. This will result in a stronger tourism and service sector in Thailand, ready to welcome a new wave of travelers both domestically and internationally.

In addition to ISO standards, the GBAC Star standard is one of the two internationally recognized standards, accepted in the United States, Japan, and South Korea. Therefore, any establishment that displays this emblem will be acknowledged by travelers, especially those traveling independently or in tour groups.

Currently, there is an encouragement for more agencies or businesses to participate in the GBAC Star standard assessment, which is another standard that allows visitors to Thailand, whether they are business operators, tourists, or visitors, to respond positively across all groups. This will help attract even more tourists to the country.

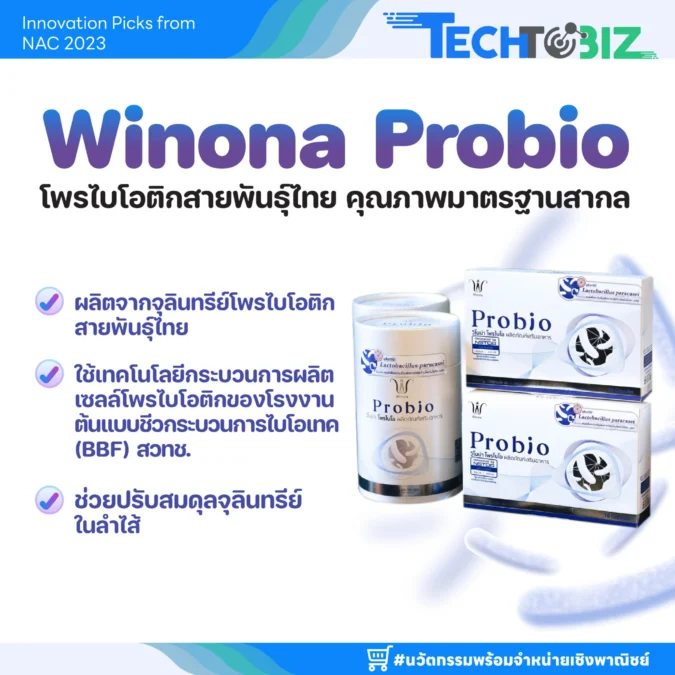

Winona Probio is the first Thai strain probiotic product for women, developed by the National Center for Genetic Engineering and Biotechnology (Biotech).

This research project is a collaboration with the Faculty of Medicine at Srinakharinwirot University and Winona Feminine Co., Ltd. “Winona Probio” is also the first innovative dietary supplement product from Thai strain probiotics in the country, produced from live microorganisms that have been isolated, researched, developed, and tested for efficacy on Thai individuals.

The highlight of Winona Probio is that it is made from Thai strain probiotics, Lactobacillus paracasei and Bifidobacterium animalis, which contain a high number of live cells. Its probiotic properties have been validated, and the product is registered with the Food and Drug Administration (FDA).

Winona Probio utilizes the probiotic cell production technology of the Bioprocess Prototype Factory (BBF) under the National Science and Technology Development Agency (NSTDA), a facility that produces food and complies with international standards such as Codex GHPs and HACCP. It also operates under good practices for using microorganisms at the industrial level, or Good Industrial Large Scale Practice (GILSP), in a controlled environment at LS1 level. BBF is equipped with experts, knowledge, and modern tools, ready to support operators in the development and production of food additives, nutrients, and dietary supplements to meet market demands and support the growth of the food and biotechnology industries.

Therefore, the development of products from Thai strain probiotics produced with Thai technology not only addresses current and future consumer trends but also helps reduce probiotic imports, decrease reliance on foreign technology, create jobs, and elevate Thailand’s new food industry to compete globally.

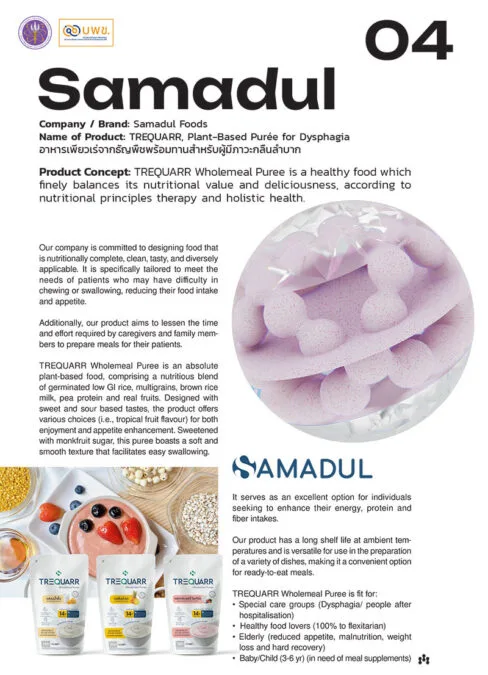

Thailand Taste of Tomorrow 2024: Fostering the Future of Food, Faith, and Flavors.

The FOREFOOD initiative (National Science and Technology Development Agency) is a platform designed to accelerate business growth. This project arises from a collaboration with the International Culinary Tourism Education Center, Faculty of Tourism Development at Maejo University, the Sensory and Consumer Research Unit at Kasetsart University, the Creative Economy Agency (Public Organization), and the private sector. Its aim is to enhance Thai food innovations, transforming them into leading products in the global market through creative media presentations.

The theme “Thailand’s Taste of Tomorrow: Fostering the Future of Food, Faith, and Flavors” will be applied during the journey to London Tech Week 2024. Here, ten startups will showcase the charm of Thai culture at Riverside Studios in London, from June 10 to 14, 2024, to attract investors, importers, and target networks, promoting Thai cuisine as leading products in the global market.

This event, organized by the Ministry of Higher Education, Science, Research and Innovation (MHESI) in collaboration with partner agencies, aims to create a phenomenon that breaks the marketing barriers for Thai food innovations. It features “a marketing promotion platform for future food innovation businesses,” engaging consumers’ five senses through innovative activities that weave storytelling with Thai culture, inspired by the mythical Himmapan Forest. Leading private-sector food companies are expected to support this initiative, helping to create compelling content around Thai food innovations that will impress investors attending the pitching sessions of the ten Thai startups.

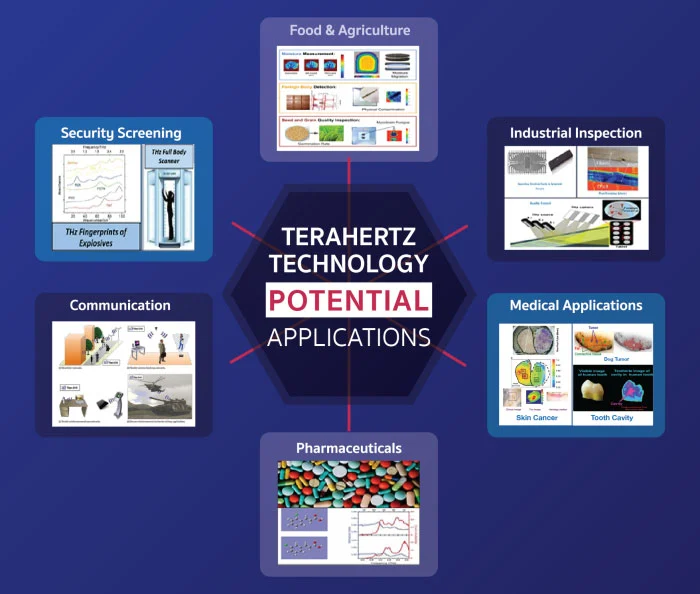

Terahertz Technology Platform to Enhance Thailand’s Electronics and Advanced Measurement Industries

The National Electronics and Computer Technology Center (NECTEC) under the National Science and Technology Development Agency has developed a terahertz technology platform aimed at enhancing Thailand’s electronics and advanced measurement industries. This platform emerges from NECTEC researchers’ desire to strengthen the commercial viability of terahertz technology through pilot projects developing two key technologies:

- Photoconductive Antenna (PCA) for Terahertz Signal Reception and Transmission.

This technology is one of the methods for producing terahertz signal reception and transmission devices, specifically the Photoconductive Antenna (PCA). It relies on the principles of generating and receiving terahertz signals through short-lived electric currents created by moving electrons around the antenna, which acts as a conductor when illuminated by a laser. The material properties are crucial in the development of the PCA.

Terahertz Time-Domain Spectrometer.

This spectrometer can be used to analyze the spectrum of substances or materials, which possess unique characteristics specific to each substance. It can also be utilized to verify the properties and functions of other terahertz electronic devices, such as those involved in communication signal reception, modulation, and distribution. Additionally, it includes basic components for applying terahertz signals in developing other technologies within the country.

- TeraBoost Metasurface Reflector.

In the near future, advanced technological devices that are critically necessary include equipment for advanced wireless communication systems such as 5G and 6G. This will enhance the potential of research in Terahertz communication (6G and beyond) to meet the demands of electronic communication devices operating in the terahertz range by 2030, which is inevitable.

The research team recognizes the importance of developing such equipment, focusing on the development of devices that receive, adjust, and distribute communication signals to support 5G and 6G communications. Testing results of a metamaterial reflector prototype on the 5G NR network at a frequency of 26 GHz indicated that it could increase signal power by up to 17 dB (approximately 50 times) at a lower installation cost than the current technology that uses signal repeaters.

The success of the Ramathibodi Tumor Biobank, the first biobank for cancer certified to ISO 20387 standards in Thailand, comes from the Faculty of Medicine, Ramathibodi Hospital, Mahidol University.

The Cancer Center, under the group of centers for excellence, has successfully developed the Ramathibodi Tumor Biobank to receive ISO 20387: 2018 certification for biobanks, becoming the first in Thailand. This expands continuous research access at all levels. The establishment of this project aims to serve as a repository for high-quality clinical samples, providing a central hub for biomedical cancer research assistance for medical personnel, enabling them to create new research and innovations for diagnosing and treating Thai cancer patients.

Moving forward, the success of the Ramathibodi Tumor Biobank will be leveraged to become a source for storing human biological samples for clinical research projects and organizations interested in it, including the sale of Ramathibodi Tumor Biobank software under the patent of Mahidol University, which is a biobank management system with international standard equivalence.

In the long term, there will be plans to open a service for preparing human biological samples for research, promoting inter-institutional research both domestically and internationally, to foster new innovations in diagnosing and treating cancer within Thailand. This includes the development of methods for early detection of cancer, which will help improve treatment success rates, allowing cancer patients to live longer and improve their quality of life. It will also reduce dependence on foreign technology and lessen the economic burden on the country from the costs of cancer treatment, which will decrease in the long run.