Support for the production of high-value products from xanthone extracted from the peel of organic mangosteen using advanced industrial chromatography technique.

On April 1, 2022, Assoc. Prof. Siree Chaiseri, Ph.D., Director of PMUC, along with the High Valued Food Program Subcommittee, visited the project to learn about the production of high-value products from xanthone extracted from the peels of organic mangosteen using advanced industrial chromatography technique at Kasetsart University, Bang Khen Campus.

The primary objective of this project is to design, build and develop a semi-industrial high pressure liquid extraction system to extract active ingredients from agricultural products that can use both ethanol and carbon dioxide solvents, and to expand the production of xanthone from mangosteen peels from laboratory level to commercial production in order to get high value products Nano-emulsion gel containing xanthones from mangosteen peels for the treatment of bedsores, which has been clinically tested in industrial production by Dr. Udomluck Sukatta, Ph.D. (Project Leader) Prof. Methee Saisriyud, Ph.D. Kasetsart University and Assoc. Prof. Rattaphol Asa Sucharit, Ph.D., Thammasat University and their team are the research team receiving the grant.

PMUC has provided 3 pieces of equipment, namely an explosion-proof rotary evaporator, a centrifugal purification separator and a rheometer.

Nano-emulsion Xanthone Gel for the treatment of bedsores – research achievement from Thammasat University

This research achievement from a Thammasat University research team to obtain pressure ulcer treatment products, which has reached the clinical study stage, was based on the study of physiochemical properties by assessing the ability of xanthones to destroy bacterial skin cytotoxicity, the ability to multiply and move skin cells, as well as assessing the ability to heal pressure ulcers in laboratory animals. The origination of this particular research on the use of mangosteen peels, which is a common waste product from agriculture, was based on basic research in alternative medicine and Thai traditional medicine, where it was discovered that xanthones in mangosteen peel are effective in treating digestive diseases, urinary tract diseases and skin diseases. In a study titled “The efficacy of topical mangosteen pericarp extract cream on wound healing in Swiss albino mice” the use of mangosteen peel extract in a cream to heal wounds was discussed. The nano-emulsion gel has stabilizing properties and helps to increase absorption, increase skin adhesion, enhance the therapeutic effects of other medicines, increase effective bio-availability, and support effective delivery of drugs into the body. It is suitable for use in treating pressure ulcers that are deep under the dermis, which may spread to the musculoskeletal layer.

The study results showed that Xanthone nano-emulsion gel for the treatment of bedsores was chemically and physically stable, had the ability to multiply and stimulate the translocation of skin cells involved in wound healing, did not cause toxicity, and had good properties to promote pressure wound healing in laboratory animals

Model production plant for producing pre-biotics from enzymes.

Another research project, for which PMUC provided funding to the research team of the Faculty of Agro-Industry, Kasetsart University, is the enzymatic pre-biotic production prototype project, with Assoc. Prof. Suthiphan Kaewsompong, Ph.D. as the project leader. The research objective was to scale up the enzymatic pre-biotic production process at the model plant level in order to obtain sufficient prototypes of pre-biotic products for market testing, including the purification of pre-biotics in large quantities which would enable the continued production at the industrial level. In this effort, PMUC has provided support in the form of equipment for use in the production of pre-biotics with enzymes, consisting of model factory level lipid extraction kit, enzyme digestion tank set for liquid raw materials, enzyme digestion tank set for solid raw materials, and a chromatographic separation/purification unit.

The project to develop a prototype process for enzyme-based production of pre-biotics is an example of funding support by PMUC to enable the private sector to expand the enzyme pre-biotic production industry, allowing entrepreneurs an opportunity to test the marketing of prebiotics in order to ultimately expand to full production of health foods. Furthermore, the equipment provided can be applied in other enzymatic processing projects to provide services to researchers interested in creating product prototypes from enzymatic processing at the prototype factory level. In addition, Kasetsart University also has a plan to develop services for those interested in a one-stop type of service in the form of a streamlined operation competitive with the private sector services, operated by a quality team of professionals.

Prototype production plant to support SMEs in developing innovative food products from agriculture for the country.

PMUC has supported the development of infrastructure in an effort to scale and upgrade agro-industry research to the industrial level. Kasetsart University has a mission to develop the prototype factory by building upon the existing infrastructure and adding on necessary components. The aim is to expand results from laboratory-level research and to test scaling up of production by providing research services to industry especially small and medium sized entrepreneurs to enable development of innovative food products to increase the value of agricultural products for the country. A fully integrated factory has been developed to meet the needs of the private sector, driving the production of high-value food ingredients in Thailand, and stimulating the development of more food innovations.

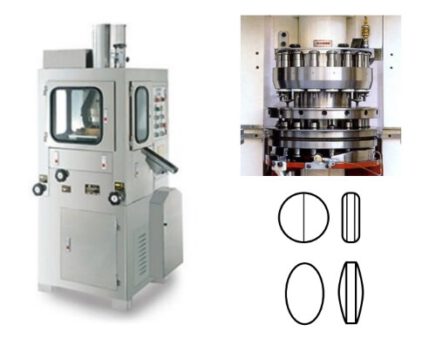

Equipment provided by PMUC includes a centrifugal separator, a microwave extractor set, a semi-prototype factory cross-flow filter machine, a particle size reducer (Microfluidizer), a fluidized bed spray coater, and a rotary tablet press machine.